BOBCAD CAM V24 GCODE PRO

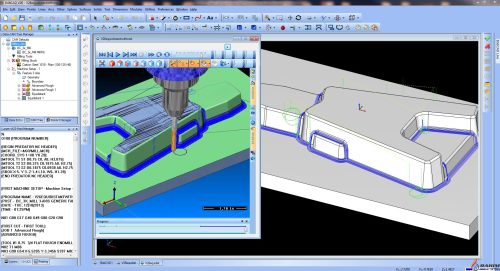

The 3 Axis Mill PRO software offers all of the CAD Design functionality that BobCAD-CAM has to offer for 2D& 3D part design and file importing. The latest BobCAD-CAM 3 Axis PRO software allows you to quickly and easily program 2D& 3D parts for your CNC milling machine.

BOBCAD CAM V24 GCODE CODE

This is the code I get using the post you uploaded that you made changes to.ġ) it's posting a G20 by using the units of the drawing.ģ) It's being put back into a G21 at the end of the program. BobCAD-CAM v25 2D & 3D CAD/CAM Software 2&3 Axis Mill PRO & Training Videos. It's in a different place for V24 vs V27 so if you let me know what version you are running I can tell you where to set your clearance plane.Īlso if you want you can email me you post and I can make these changes for you. You can edit this line in your post and have it post a Z move first This block will move in X and Y first ( as if you have a tool changer and the tool is already at clearance ) N,rapid_move,absolute_coord,work_coord,force_x,xr,force_y,yr,s,spindle_on You'll either see and X Y move and then a Z or you'll see a Z move then X Y You'll need to look in posting blocks 2,3, 4 for how you inital move is made. There are no special scripts needed to perform these actions.Īs far as the Clearance move at the start and end of the program. So you can use measure_mode in the start of the program to post in the units of the drawing, and you can hard code "G21" in at the end of the program to return the unit mode on the controller to metric. If you post is not using the variable then you'll like see the unit value in " " which means it's hard coded into the post.Ĭodes that are posted at the start of every job come from posting blocks 0 and 2Ĭodes that are posted at the end of ever job are from posting blocks 5 This variable will look at the units of the drawing and post a G20/G70 or a G21/G71 based on if you are in inch or metric. In the post there are different blocks listed by number on the left.ĭepending on what version of the software you are using there are different variables that accomplish different things. This video click will go over the basics To edit the post processor you need to open it in a text file.

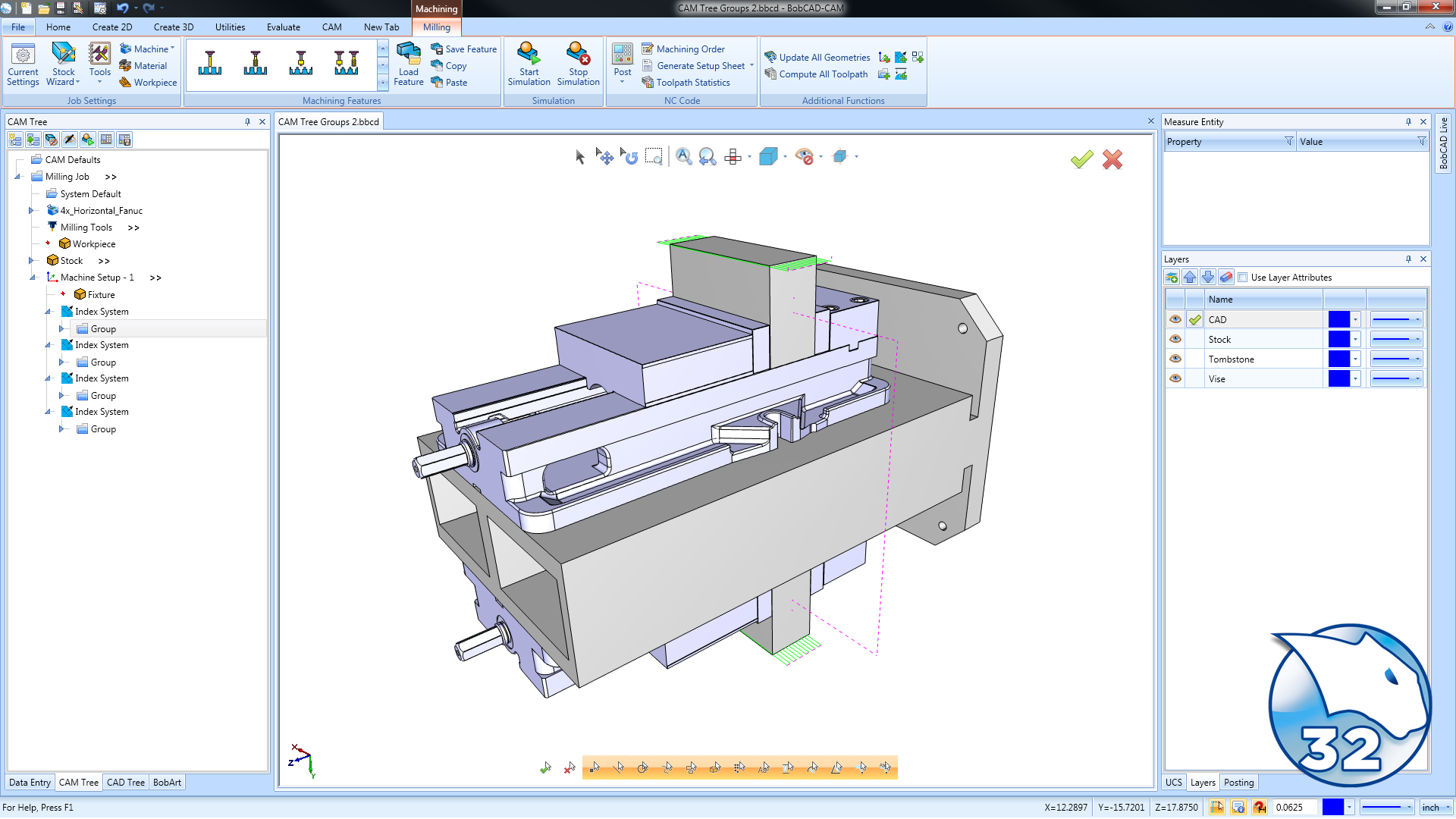

There are 2 posting blocks you need to edit to accomplish what you are looking for.ġ) Are you programming a metric file that you want to post in Inch?Ģ) Did you want the posted code to be based on the units drawingģ) Your clearance plane, did you want it defaulted to the. With revamped mill drilling, the addition of custom tools, tabbing for profiling, and wrapped/4 axis tool-path enhancements, this is the most versatile version of BobCAD-CAM yet.The post edits you are asking for are easy to do.

We've added a completely new Mill Turn module capable of handling the most complex of machining jobs and made numerous system improvements including better surfacing tool-paths, smarter hole making capabilities, more tool type options, an improved simulation, and more. The latest version packs more features and system improvements than ever before. for design combined with toolpath and complete G Code producing functions that makes your CNC software. The new software includes a host of time saving features including Dynamic Machining Strategies that reduce clicks and allow machinists to spend more productive time cutting. Tool-path programming is easier than ever thanks to advanced surfacing strategies and a simplistic wizard driven interface that guides you through the entire process of setting up tool-paths, eliminating the guesswork and improving workflow efficiency. BobCAD-CAM provides programmers with a seamless transition from the design process to tool-path programming, simulation, and g-code processing without ever leaving the BobCAD-CAM single window interface. Advanced CAD design tools allow you to create everything from simple 2D models to complex 3D parts.

BobCAD-CAM CNC programming software is a fully integrated CAD-CAM product for 2-5 axis CNC milling and turning.

0 kommentar(er)

0 kommentar(er)